Last year I attended Revit Technology Conference (RTC) in Delft and I had a great experience. It was a compact and small conference, high quality lectures, and it was well organized even thought it was the first time they arranged a RTC in Europa. The same qualities seemed RTC in Dublin to share. The lectures I had signed up for looked promising, the city seemed to have a lot of atmosphere, and they had increased the length of the conference with one day. So this time I had high expectations, and from my office, Dark Architects, we sent 7 architects in total to this conference. That is 13% of the entire office, so I really hoped that they would not be disappointed.

From left: Thomas Benedict Holth, Håvard Vasshaug, Kaja Kittang Kvande, Lars Ribbum, Vilde Aspen, Arne Folkestad Bjelland, Ricardo Sousa

As usually the conference started with Chairman’s Introduction & Keynote Presentation and it was a great start. Especially when Paul Doherty from «the digital group» took the stage, and talked about how the digital technology would change the world in the future. He explained the value of making big data understandable and available in a live context. He used examples on how firemen could use BIM technology together with other information that was available in the area, showed us a new Google project called Flux.io, and he showed us how they are testing robots in the states to do surveillance in kinder garden. One of many tasks the robot is going to perform is to report if a child is going towards a car that is suspicions based on face recognition and by scanning number plates. In fact, his vision of the future made me nervous and uncomfortable regarding the many issues regarding surveillance and privacy. And then, his last example was how Watch_Dog We are big data collect and visualize the absurd amount of information that is already open and available on the web.

Paul Doherty from «the digital group»

Wow, is this how we want to use technology in the future? Is suddenly the movie «Transcendence» I saw on the plane to Dublin not that far off after all? One of the best speakers last year at RTC in Delft was Kelly Cone where he explained how Beck Group used 3D scanning in a project. This time he titled his lecture “Drawings? We don’t need No Stinkin’ Drawings” and he explained actually how much it costs in time to produce and maintain a drawing. In a recent project the Beck group tried to reduce the number of drawings to a minimum. They started listing 169 sheets of drawings they normally would produce, but by asking the consultants what they actually needed of information; they reduced it with 98 sheets. That is a lot of money saved. He then continued talking about model based fabrication and briefly talked about how this would impact the industries. Next speaker was Julien Benoit with “You can count me like one, two, three, I’ll be there”. The best part was his explanation of the power of using parts when making schedules and how he used Dynamo to import and export information to building elements in the model. That we all like it sexy was how Jay Zallan approached the importance of making a well modeled BIM model. And from there Anthony Hauck from Autodesk took the stage and talked about the visions Autodesk have for Revit and other application. He made it clear that Revit should be seen as a client that not will do everything, but rather be seen as one of many tools in the ecosystem. He also demonstrated a couple of cool new application like A360 and project Akaba. I am looking forward to testing out these tools soon.

Anthony Hauck from «Autodesk»

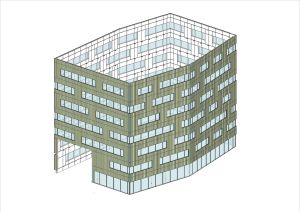

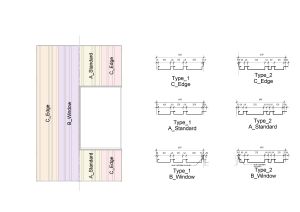

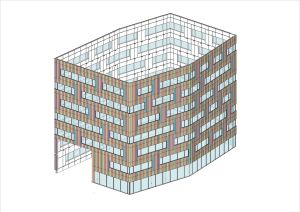

After wrapping up the day with Glorious Gadgets, where they showed new gadgets and technology, first day of RTC officially over. The second day started with Brian Mackey talk about “Every day use of adaptive components”. It’s was a good introduction with some basic tips of how to use it in a regular project, and a good reminder of how useful adaptive components really can be. In these technology conferences it can be almost to much attention to drawingtools and skills, and therefore I really enjoyed the next lecture «The good, bad, and ugly of sharing a design model with the contractor» by Michael Whaley and Josh Lowe. They discussed how the contractors should use the models during the construction phase of a project, and the pros and cons for the different delivery methods they use in the US. And now I want to talk about Dynamo. Håvard Vasshaug started in many ways a RTC marathon of Dynamo sessions this year. And what a great start! My colleague did a live demo, where he builds his formulas and nodes from scratch. It was impressive how much he had time to do in his limited time, but that Dynamo did not crash during his hole session was maybe even more extraordinary:)

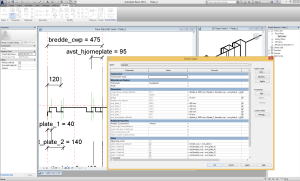

Håvard Vasshaug from Dark Architects

Andreas Dieckmann, Julien Benoit and Peter Kompolschek did continue with Dynamo labs and sessions through the entire Saturday and they did demonstrate how powerful Dynamo can be in the daily use of Revit. Maybe the most important thing I learned in these sessions is that Dynamo can make my life much easier also with simple tasks. I am thinking about tasks like importing/exporting data to and from an object in Revit, or to extract buildinginformation for object to be placed on sheets etc. You should remember that Dynamo do so much more that only creating complex geometry.

Dynamo lab

The RTC committee has arranged another great conference. It was both inspiring and fun, professional and social. The third RTC in Europa will be in Budapest next year, and then I hope to see even more European speakers. I think that would increase the popularity in general and make RTC EUR stand out from the rest of RTC.